| Particulars | Specification of water Jet Looms |

|---|---|

| Reed Width In CM | 150, 170, 190, 210,230,260,280 |

| Electric Power (KW) | 1.5 Kw, 150 Cm to 190 Cm, 2.8 Kw, 210 Cm to 280Cm |

| Water Adsorption Fan | Non-Powered (On right Side) |

| Control Panel | Brand: Xinlio, Shane |

| Feeder | Shane (SHJ-P) or Xinlio (XL-35) |

| Yearn Gripper | Electronic |

| Reed Holder | Stainless Steel |

| Slider Holder | Stainless Steel |

| CVT | Shimpo (Japan) |

| Nozzle | Model: (2 pc) MDH (60*20) Korea (45*20) |

| Plunger | Model: 39*28 (1 pc) MDH |

| Pump Spring | Awa, Japan |

| Shedding | Crank type plain tappet, Cam Shedding Niupai Model, Doby Motion Niupai Model |

| Take-up | Mechnical & Electronics |

| Late-off | Mechnical & Electronics |

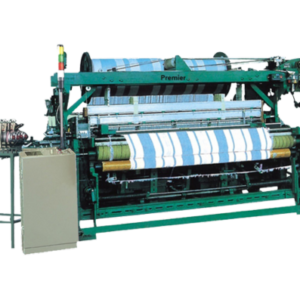

Water Jet Loom First Make in India

SD-822

SD-822 series water jet loom is based on original 622 series but integrated with all the advantages of the 408 series. Re-optimized design and thickened frame improved the machine’s reliability, production efficiency and enlarged the weaving range.

- Width : 150-380 cm

- Adopt thicken frame

- Shedding : Plain, Cam Motion or Dobby

- Non-power, energy saving blower

- SD-822 series water jet loom parameter is according to or higher than “Water Jet Loom Industry Standard” FZ/T 94054-2009

- Power Saving Mechanism

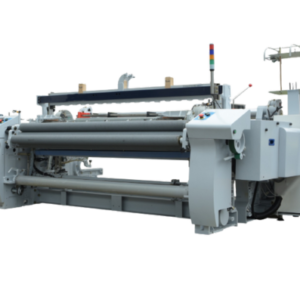

SD-8100

SD-8100 series water jet loom is integrated with new technology and the advanced loom concept. It has further improved and innovated existing technological conditions. SD-8100 series make new breakthrough on production ability, cost savings, environmental protection and energy savings through new frame and rocking structure and weft insertion system. SD-8100 series water jet looms are more stable and efficient to adapt to the continuously expanding textile field and requirements of the market.

- Eccentric rocking shaft: Reduces beating vibration in running, increases stability, better loom weaving efficiency for fine denier and high-density fabric

- New frame structure: Frame height reduced 20mm, lowering the looms’ center of gravity which in turn leads to reduced vibration and improved stability; Also leads to better operating convenience; Four stay bars in frame increases longitudinal support and reduces the loss of spare parts; Again, this helps improve frame stability and overall production efficiency of the loom

- Adopts redesigned and enhanced shedding structure that improves rigidity and stability of the shedding

- Adopts new loom control system and an efficient, energy saving motor, which in comparison to traditional machines, reduces efficiency loss and saves more energy

- SD-8100 series water jet loom parameter is according to or higher than “Water Jet Loom Industry Standard” FZ/T 94054-2009